You can look up at a product called exposed aggregate if you want to have concrete outside your business or home. This is known to differ from all other building materials which are available. It is same as concrete but is one layer less.

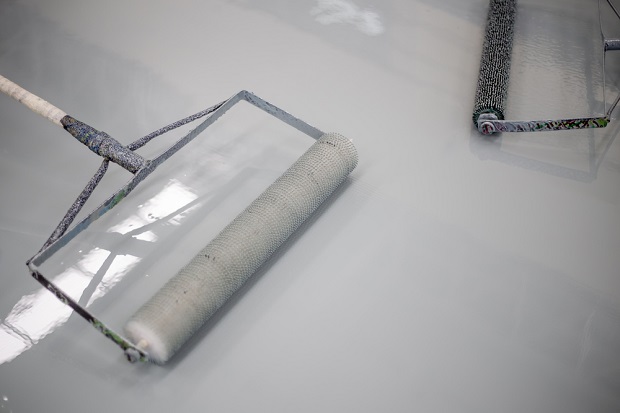

- This means the outermost layer is removed and the aggregate below is revealed. Aggregate concrete is mostly used for large scale building projects and the composition of the aggregate concrete needs to be finished well before it is used for major building purposes.

- The first and the foremost benefit of installing exposed aggregate is that it very decorative. It is very beautiful in appearance and therefore can be used wherever you want.

- This is available in different sizes, colors and texture variations also. Each of the installation done will be different from the first one and therefore it can give a unique look when the installation of the same is completed. You can hire quality concrete aggregate installers to get different colors and textures for the concrete. Using variant colors for different places will also be a good option.

|

| Aggregate Concrete |

Where can you install the Concrete Aggregate Layers?

You can lay it in your home or then can also choose this as an option for your driveways or patio flooring. This is an ideal option, especially for bathrooms.

- If you have seniors or children who are prone to falls but are not extra careful then this can be the right choice to make.

- If you have planned for any type of a walkway, this should be the first material to think on. The whole exposed aggregate can provide an anti-skid formula for the sealing and protecting of the ground.

- The main reason for the same is that these are weather resistant and also scratch resistant. It does not chip or break easily even if something sharp falls over it. Except some occasional clean this type of flooring does not demand a lot of maintenance too.

- The cleaning can be done with some soft liquid wash. You can then use lukewarm water to clean it and get rid of all the dirt, dust or stains if any.

|

| Exposed Aggregate |

Exposed Aggregate is very easy to Install and Maintain:

Another benefit of exposed aggregate is that it is very easy to install this type of flooring. You can either do it yourself by mixing all the composite material and making the floor or then can also hire a professional.

- Doing it yourself may sometimes be difficult as you may not know the measurements and mixing proportions right.

- Hiring professional masons for this work can be a good idea. They will not only help you place it right but will also mold the material whenever necessary.

- You can save your money on finishing as it is one thing which is not required and thus can be omitted.

Finding and installing exposed aggregate is all about taste and liking. Before making a decision it is important that you analyze your needs and then choose to buy it. You can only then decide what is important and the amount of money you will have to spend on the material purchases and installations. However, when the installation and maintenance of the exposed aggregate comes into being, then you must consider the season, like if it is monsoon, then the quality of the aggregate can get damaged.

Exposed aggregate contains of the exposed parts of the natural stones, so due to heavy rainfall, even the color and the texture can vary a lot. Choosing exposed aggregate over other materials will always be a wise choice to make as it is very versatile.