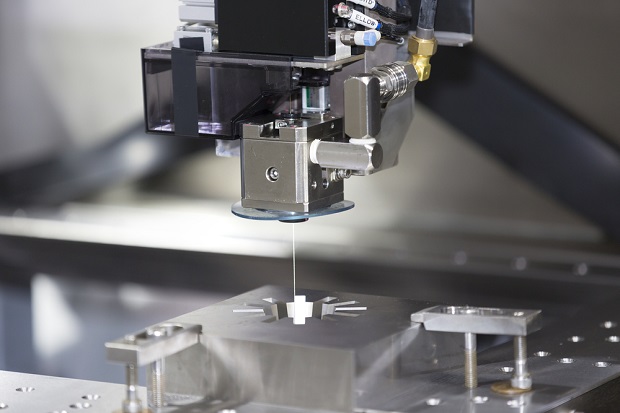

CNC precision machining is known to have contributed to different industries widely. There are several objects that one uses daily which are manufactured with the help of the technique. When it comes to offering a shape to any industry equipment or tools that are used in any factory, this machine, and its technique is of great help. It offers a high-level accuracy for shaping the products because, the machinery employs sophisticated software like the CAD or CAM to get the best and accurate blueprints for further execution.

|

| CNC Precision Machining |

How effective are the techniques employed by the CNC precision machining as opposed to skilled professionals?

- The most common doubt or debate that does the round is the precision machining can cut and shape only specific materials whereas, the CNC precision machining can cut copper, titanium, graphite and even plastics with accuracy.

- As compared to the skilled labor, the CNC precision machining will easily surpass the regular cutting and shape undertaken by the humans. These machines come with super advanced software to undertake any kind of designing and cutting.

- This kind of machinery reduces errors as well as required time to undertake any project. Many factories and industries are investing in the CNC precision machining as it helps them to cut down on the number of workers and achieve maximum productivity.

- Since the CNC precision machining comes with software that can be programmed there is no chance for any human error and it also saves money on the cost of manufacturing.

- These machines also cut down the risk of accidents significantly.Even the minutest part can be undertaken with utmost safety and accuracy. So, the owner will not have to worry about any employee risking his life over any process that is complicated.

- The most interesting feature of the precision machining is that it comes with automatic features. When it comes to cutting, shaping or assembling, this machine can undertake even the trickiest of the job efficiently.

- All the errors that are prone to manual assembly are ruled out because of the precision machining. Such machinery is certainly helpful when it comes to tricky processes which are to be undertaken on a larger scale. Thus, handling giant projects with precision and lesser production time is possible with the precision machining.

- When it comes to manual production, the amount of waste is considerably more than the precision machining. The companies usually spend a lot of money on accessing the raw materials. Post production, they are left with a huge amount of waste. However, when it comes to precision machine, the waste is reduced and helps the company to save money on high-quality material.

|

| Precision Component |

Several companies have benefitted greatly by employing the use of precision machinery. They are impressed with the efficiency as well as a boost in productivity. At the end of the day, every company looks out to save as much money as possible on the production so that it gains profits. With the help of such technology, it is possible for the company to serve the best and accurate products at the most competitive rates. Dealing with the competitors is also easier as one can handle the projects efficiently irrespective of the deliverable and deadlines.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.