Epoxy coating is the term used for any thick protective material. This coating can be used for a variety of surfaces and materials. It can be used from floors to appliances and these are also used for the electronics. The reason why epoxy coatings are used is to protect the material from wear and tear or damage.

|

| Epoxy Coating |

#1. In order to use the epoxy coatings, there are wide ranges of materials that can be used. These are made of epoxy resins that are also called as polyepoxides. These materials are not only durable but these are also resistant to chemical corrosion as well as rust. They are also easy to use. The way this is done is that a concentrated powder or liquid is painted or sprayed over the surface that needs coating. This dries very quickly and normally a reapplication is not required. If it is required, it can be done when the drying of the first application is completed.

#2. Epoxy coatings are used especially for refrigerators, washers or even dryers and this not only gives them shine but also scuffs, marks and wear and tear signs are resisted as a result of it. These have aesthetic appeal and these are more importantly used when you want to prevent the overheating of electronic items. When used for insulation of pipes, leaks can be prevented and the pipe walls can be strengthened against changes in temperature, corrosive liquids and cracks.

#3. The reason why this is used is that this resists not only corrosion, heat, ultraviolet rays but it also lends stability, toughness and resistance against abrasions. This also has a property of adhesiveness to various kinds of surfaces and can also be used for glass, fibers, metals and other materials.

#4. Epoxy coatings use an epoxy resin as well as a polyamine hardener. This hardener helps in being a catalyst for the polymerization. It is due to this polymerization that cross linking is done of the two materials and the compound is given strength as a result.

|

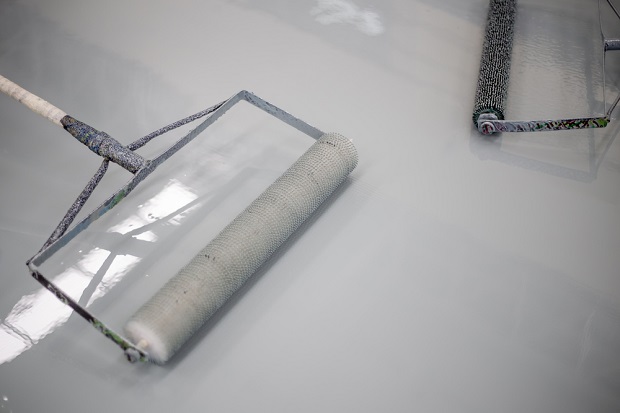

| Epoxy Floor Coating |

#5. This coating is thermosetting. The reason for it is that by mixing the resin and the hardener, polymerization is triggered and in this way the heat is generated. Some of the applications need this extended heat and extended curing and some do not require it to that extent, hence the curing period depends vastly. It could extend from a few minutes to even days.

#6. Epoxy coatings are either powder based or they are waterborne. If they are waterborne then the curing is done at ambient temperatures. This has low flammability and is non hazardous. Also it is easier to transport as well as to handle and finally the cleaning up is much easier. On the other hand, the epoxy powder coating requires high temperature which is controlled for the curing to take effect. This is used normally for coating of refrigerators, dryers, washers and similar appliances. It is also used for the underside of a boar or water crafts and even for the floors of warehouses. The more sophisticated type of these powder coatings are used when steel pipes need to be prevented from corrosion. This is normally used for those pipes meant to transmit water. This epoxy coating is material that has high performance and this increases the life of the material it is added to.

In order to get the right finish, the proper consistency is needed. The hardener and resin need to be combined in proper proportions and these are available in liquid forms with low viscosity when it is at room temperature. This way it is easy to handle.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.